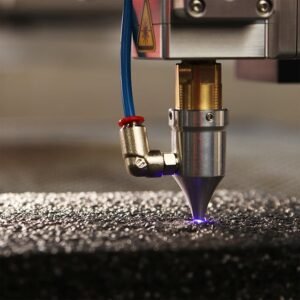

High-Precision Laser Cutting Services

At OKH, we utilize state-of-the-art CO2 and Fiber laser technology to deliver extreme precision across a wide range of materials. As the primary step before bending or fabrication, our laser cutting service ensures that your project starts with the perfect foundation.

Technical Specifications & Capacities

We handle a broad spectrum of materials with a high cutting tolerance of +/- 0.1 mm.

Maximum Material Thickness:

Mild Steel: 25mm

Stainless Steel: 20mm

Aluminium: 12mm

Wood: 30mm

Acrylic: 10mm

Copper & Brass: 3mm

Maximum Cutting Area:

Sheet Size: 3,015 mm x 1,524 mm (For larger requirements, our fabrication team can join sections to meet your specifications.)

Our Advanced Machinery

Our facility is equipped with industry-leading technology to ensure speed and accuracy:

Bystronic BySpeed 3015 (5.2kW)

Bystronic ByAutonom 3015 (4.4kw)

Customized Fiber Laser Machine (3.3kW)

Key Benefits of Our Laser Service

Rapid Prototyping & Speed: We produce complex components in a single step, allowing us to beat deadlines and deliver prototypes in a fraction of the time.

Cost-Effectiveness: Laser cutting eliminates the need for expensive tooling and jigs. Our trained staff optimizes material nesting to reduce wastage, passing those savings directly to you.

Superior Edge Quality: Our lasers produce clean, attractive edges that require minimal finishing, whether you are working with hollow tubes, open sections, or flat sheets.

Design Flexibility: From simple industrial brackets to intricate custom shapes, our technology allows for total creative freedom with high-level accuracy.

Versatility Across Materials

Beyond standard metals, we offer cutting services for plastics, wood, and various metal alloys. Whether you need a single custom piece or a high-volume production run, we guarantee a quality-controlled process that meets international standards.